ECO SILENT

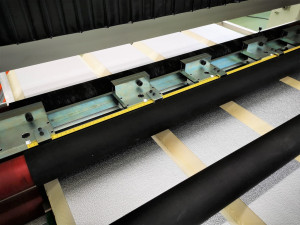

The new ECO SILENT is a CNC Machine (Computer Numerical Control) studied and produced with the latest technologies with the purpose of cutting straight and special parts with Blades (i.e. elbows, Y shapes, offsets, reducers) from pre-insulated PIR panels (Polyisocyanurate) or similar sandwich foam-based materials, used for fabrication of HVAC ducting (Heating, Ventilation, Air conditioning).

The new ECO SILENT is a unique machine cutting pre-insulated panels by means of BLADES, not using milling (or routing) tools. The new ECO SILENT is extremely “user friendly” and the latest version of our dedicated CUT EXPERT software easy to manage. Due to a perfect product process industrialization CGM Srl propose to his valued customers a very high quality machine at the minimum cost. The standard machine is completed with a large quantity of accessories and devices dedicated to reduce the production time and generate the best quality of finished product.

The standard machine includes:

DOWNLOAD MANUAL

Specifiche tecniche

CNC Cutting Machine Mod. ECO SILENT

| MIN PANEL DEPTH | 10mm |

| MAX PANEL DEPTH | 30mm |

| MAX ALUMINIUM WIDTH | 200µm |

| MAX PANEL WIDTH | 1200mm |

| MIN PANEL LENGTH | 600mm |

| MAX PANEL LENGTH | UNLIMITED |

| WEIGHT OF MACHINE | 1.200 Kg about |

| SIZES OF LINE MOUNTED | 840 X 190 X h. 165 cm |

TDC tool for multi straight cut with cutters

The cycle of functionning is inserted in drive of machine ECO SILENT. With few and simple operations is possible to cut as far as 4 strips with 45° cut on the same panel. The TDC tool permits to have only one machine for the milling mould cut and for the straight cut with cutters.

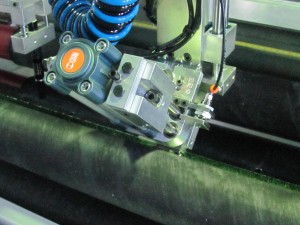

Tool for 45° cutting not passing

This tool permits to do cutting at 45° without cutting the aluminium paper on the inferior part of panel. It permits to produce pieces where it is not necessary to assembly much parts to obtain the finished product (for example reductions, plenum, etc…).